WiFi Extruder Controller

Two thermistor input

One thermocouple input

One power mosfet output

Price:$59

Details

–

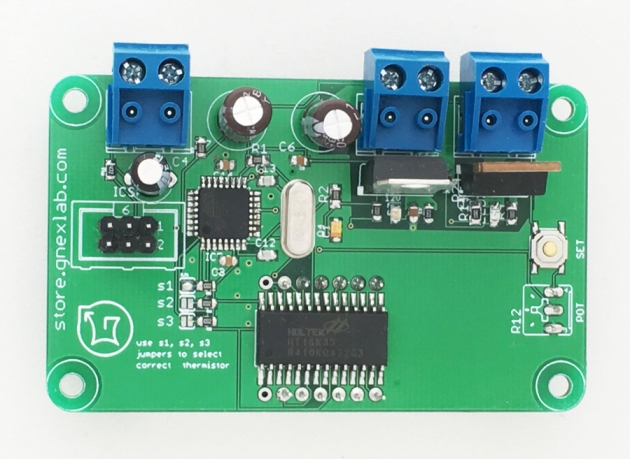

Seven-Segment Thermistor Extruder Controller

One thermistor input

One power mosfet output

Price:$47

Details

–

Seven-Segment Thermocouple Extruder Controller

One thermocouple input

One power mosfet output

Price:$47

Details

–

–

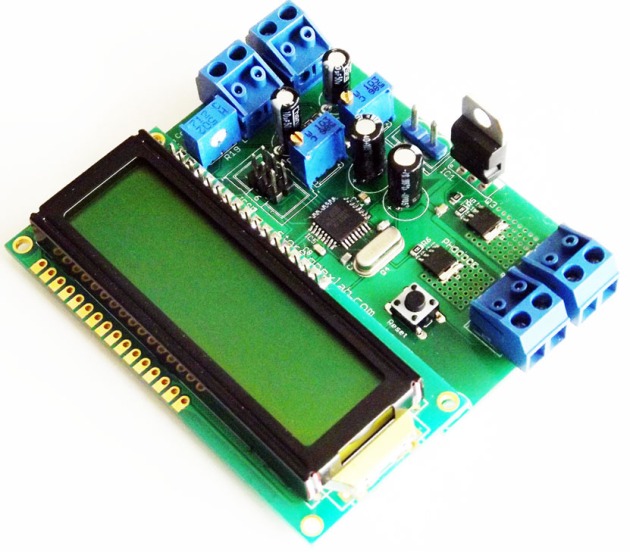

LCD Thermocouple Extruder Controller

Two thermocouple input

Two power mosfet output

Price:$59

Details

–

Hello!

Is it going to be available again anytime soon? (Seedstudio is out of stock and I cannot find it anywhere else).

Please let me know if there are other stores have it in stock.

Thank you!

I’d like to find out more? I’d like to find out

more details.

What kind of info do you need I am here to help you

Hi, I buy your LCD Thermocouple Extruder Controller from seedstudio but when i plug it, its never power up, never get a reply from seedstudio about replacement or refund, so i build one myself base on your design, but i was unable to compile your code you post, do you have any new or update version of your code ?

Hi Alain,

We are not working with seedstudio any more. But I am here to help you. We also do not have the Thermocouple board in stock. We have one channel version at the moment. There is no update for the LCD board software. You can take a look at the code of the seven segment board which is nearly same. seven-segment thermistor board

By the way a new Extruder Controller board with wifi capability is on the way. I can send you one If you like to test it.

If there is another thing I can help you please write here or to me from ne@makerstorage.com

I am really loving the theme/design of your web site. Do you ever run into any browser compatibility problems? A few of my blog readers have complained about my website not working correctly in Explorer but looks great in Chrome. Do you have any tips to help fix this issue?

Howdy, any thoughts of porting your plugin to mach4? It’s finally stable/mature enough. I may have a crack at it myself but am wondering if I can avoid reinventing the wheel (I.E. if you have already done it?)

Kind regards

2 years ago I decided to do that and work on it for some days. But mach4 crashed for many times and I gave up implamenting it. But If you think its the time we can talk on that.

Heh, yes I know the experience, it was truely awful, worse than a toy. After ignoring it for a year I had another look and have now been using it solidly for the last 12 months, it’s seen huge improvements, they have really ramped up the development effort and ditto for the warp9 smoothstepper plugin that I use with it. They are now at the polishing and shining stage, all of the core functionality is solid. The sdk is available by application, just an email. I was going to do an esp8266 DRO and plugin but ended up doing it with hardware directly. The changelog for the release version is available here.

Click to access Change%20log%203481.pdf

The dev version is now at 3643.

Let me know if I can be of assistance. m3chanist@gmail.com

Great to hear that It was soild now. I already (2 years before) signed an NDA with Newfangled Solutions on developing the plugin on their system. Very nice guys.

It can be great to work together on developing new hardware and software solutions on this new mach4.